USM Spraybot

The Spraybot offers a flexible, completely self-contained modular work cell. With high-end robotics and integrated work handling systems, the Spraybot can be configured to meet any factory’s production plan.

The Spraybot Surface Treatment System is designed to apply any surface treatment to parts such as footwear, midsoles and outsoles. Various non-contact treatments, like plasma, corona, priming and adhesive application, can all be processed on the Spraybot as long as the weight of the tool does not exceed the robot’s capacity.

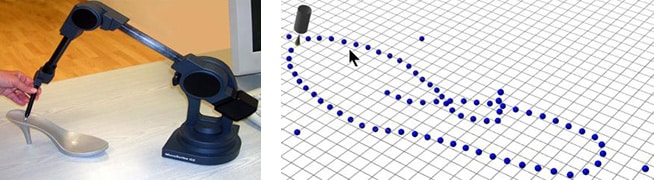

Digitizing Process

Digitizing the surface treatment path can be done on the optional stand-alone Microscribe or through the on-screen interface.

The pattern is then graded on the fly using well-proven footwear algorithms to match the profile that the vision system captures. The robot path is extremely accurate.

Solvent

PUR

Corona

Modes of Operation

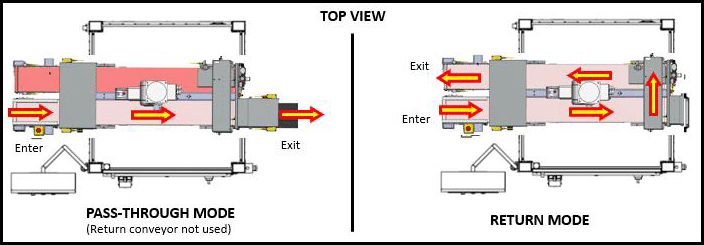

Two separate modes of operation are available depending on the production process. In both modes, the start of the process is identical. The parts are loaded on the input conveyor where they are passed under a vision system. The vision system detects variables, such as left/right, orientation and size. This information is then converted to a robot path by the on-board PC and passed to the robot for processing. Once processed, the operator can either choose the RETURN mode or PASS-THROUGH mode.

In the PASS-THROUGH mode, the parts continue on the original conveyor and exit out the side of the machine to the next process. The PASS-THROUGH mode is perfect for continuous processes, as devices like conveyors, dryers or even additional Spraybots can be integrated together.

In the RETURN mode, the parts are automatically transferred to a separate internal return conveyor where they are brought back to the operator. In this mode, one operator can load and unload the Spraybot without moving.